How We Support the Semiconductor Industry

Better Efficiency, Yield, and Profitability

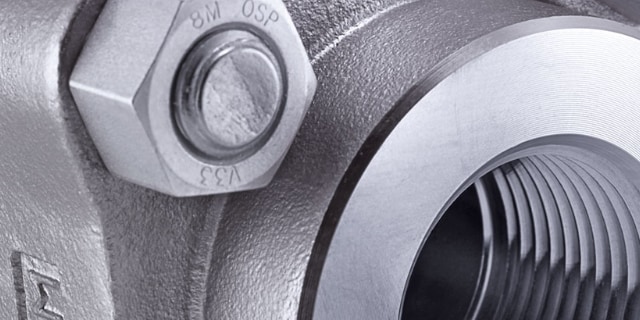

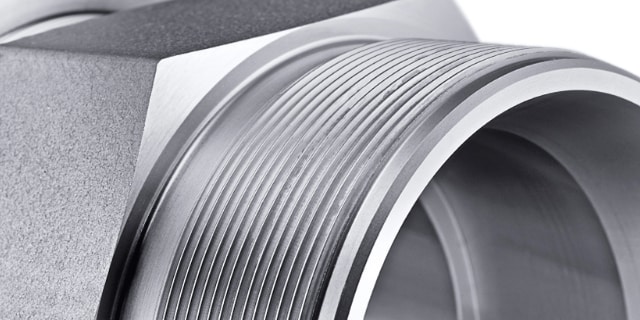

As the miniaturization of process nodes continues, we provide access to the UHP cleanliness levels and extreme dosing precision needed to maintain high yields. Our commitment to quality and process repeatability allows our UHP valve products to provide consistent performance, thermal stability, and clean, reliable changeover while helping to prevent contamination and promote safe containment. Knowledgeable Swagelok fluid system specialists can provide insights regarding which fluid system components, assemblies, designs, or material choices will help you maximize chip throughput and yield without sacrificing cleanliness or precision.

We also can work with you to enable experimentation with chemistries and processes that require performance at higher temperatures or flow rates. Our applications engineers stay closely connected with the semiconductor industry to keep up with ever-advancing requirements for process speed and dosing precision. This allows them to apply their technical knowledge, advanced software, and manufacturing expertise to develop unique solutions to help you overcome process challenges and continue innovating.

Reduced Total Lifecycle Costs

Given the cost of semiconductor production and the value of the outputs, downtime must be avoided to maintain profitability. To minimize total cost of ownership, Swagelok components are engineered to deliver consistent performance over millions of cycles in challenging process environments. We know that the exploration of new precursor gas options for deposition requires fluid system components to withstand hotter production processes and more corrosive media, and we have designed our products to last in challenging conditions so that you can replace components less frequently, minimizing process downtime and maximizing throughput.

For applications beyond chip-manufacturing tools, we provide fluid system components designed to perform reliably throughout a variety of industrial facility applications, helping fabricators avoid downtime and minimize costs related to maintenance, repair, and operations of semiconductor facilities. Local Swagelok-certified fluid system professionals can visit your facilities or connect with you virtually to offer technical support, advise on system design, troubleshoot system issues, provide fluid system training, or consult on maintenance and operational best practices to help you improve system performance. From tool installation to base builds, and from specialty gas and chemical distribution to central utility plant work, we can provide comprehensive support for your fluid systems.

Consistent Access to Products and Support Worldwide

We have the people, processes, and technology in place to give you confidence that you will receive consistency from product to product across your operations so you can in turn deliver the quality and consistency your customers expect. That consistency starts with Swagelok’s strict manufacturing process controls enforced at our 20 manufacturing facilities and is supported by thousands of associates who work together to provide product development, training, field services, technical services, delivery coordination, planning support, and additional specialized expertise as needed to help you maintain reliable performance throughout the full lifecycle of your fluid systems. Our global distribution network provides comprehensive sales, design and assembly, troubleshooting, and training support from more than 200 sales and service center locations across 70 countries, and you can also collaborate with engineering professionals with advanced knowledge of semiconductor applications at our six global technology centers.

Recognizing that component availability is critical for your success, we have invested heavily in manufacturing capacity, supply chains, and relationships with our semiconductor customers to anticipate needs and provide the products you need when you need them. With our local sales and service center-based product inventories, global supply chain, streamlined order fulfillment processes, and logistics network, you are never far from the products you need.

Safe Fluid System Operation

Fluid leaks must be taken seriously given the nature of the chemicals used in semiconductor facilities, and avoiding fluid system leaks requires choosing every system component carefully—both within semiconductor manufacturing tools and beyond. Something as simple as condensation on the outside of a chiller hose that is not properly insulated could result in slip hazards or downtime until the source of spilled fluid can be identified. To help you avoid issues such as these, we provide a comprehensive portfolio of leak-tight, corrosion-resistant fluid system components and assemblies that are properly constructed to promote safe conditions in your facilities. We carefully select materials for our components to ensure chemical compatibility, then manufacture the product and process the surfaces to enhance corrosion resistance in semiconductor manufacturing applications. Our verification protocols confirm the suitability of our products for use in conjunction with caustic materials and extreme temperatures, protecting you and the integrity of your processes.

Our experienced trainers can also provide product selection, installation, maintenance, and system design training to ensure your team members have the knowledge needed to keep your operations safe while enabling dependable long-term fluid system performance.

Efficient, Effective Facility Construction

If you are constructing a new fabrication facility, our global construction services specialists can help mechanical contractors keep projects on time and on budget, getting fluid systems operating quickly and reliably. Our fluid system specialists can provide technical support, consulting on product selection, specifications, and designs to ensure that performance standards are met. For example, we can recommend specific high-performance hoses that help simplify the design and installation of cooling systems or systems that deliver process gases. We can introduce standardized, turn-key fluid systems assemblies such as purge panel solutions for gas distribution or point of use applications, helping to reduce complexity and man hours required for installation, maintenance, and use. We can also provide comprehensive material management support on-site and off-site—including vendor-managed inventory, kitting, and strategic inventory management—to enable productivity and scheduling gains.

During equipment installation, we provide gas design engineers, mechanical contractors, and specialty chemical contractors with fluid system design and assembly, orbital welding, component selection, installation, and inspection advice and training. Our team can also help make sure that nothing is missed during tool and general utilities hookup, checking that Swagelok-built fluid system assemblies, such as gas panels, and hose connections are leak-tight and ready for startup and validation.

CONTACT KNOWLEDGEABLE FLUID SYSTEM SPECIALISTS

We know that innovation is the foundation of semiconductor industry success. Relentless advancement in electronic technology demands more complex, more compact microchips, and competition is fierce. For more than five decades, Swagelok has provided high-quality fluid system components and support to semiconductor tool manufacturers and chip fabricators to help them evolve production processes and equipment while maintaining the precision and cleanliness needed to sustain profitability. As a result, we have the privilege of working with global semiconductor industry leaders who trust us to help them increase chip yield and quality, reduce lifecycle costs, and maintain safe fluid system operations.